Civil engineering

-

1. Suspension Bridge Construction TechnologyWith the unique cable installation method of our company, which has world-class suspension bridge construction technology, we successfully completed the 1915 Çanakkale Bridge, which is the world’s longest suspension bridge, in Türkiye. Also, we have constructed innovative bridges in South Korea, as well, including the Yi Sun-sinBridge, which is the longest suspension bridge in South Korea, the Gogunsan Bridge, which is the longest single-tower suspension bridge in the world, and the Cheonsa Bridge, which is the first three-tower suspension bridge of South Korea.

-

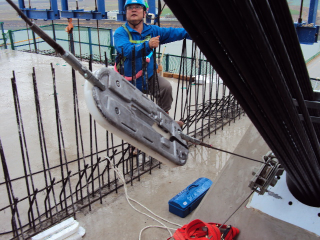

Driving winch for cable installationA winch is a cable installation machine for suspension bridges that is used to lift or pull a heavy load. Since using a winch allows the user to work fast and accurately with a single piece of equipment, there is no need to purchase and switch between many different machines, saving quite an amount of time and cost.

Driving winch for cable installationA winch is a cable installation machine for suspension bridges that is used to lift or pull a heavy load. Since using a winch allows the user to work fast and accurately with a single piece of equipment, there is no need to purchase and switch between many different machines, saving quite an amount of time and cost.- Reference projects: Yi Sun-sin Bridge, Palyeong Bridge, Gogunsan Bridge

- Intellectual property right: Registered Patent 10-1213317

-

Catwalk rope installation technologyThis is a smart technology that controls the height of the ropes used in construction, for the ships passing under the bridge. The system detects the tension of the ropes in real-time to adjust the height automatically to ensure that the ships passing underneath can do so safely, thus ensuring safety in construction work.

Catwalk rope installation technologyThis is a smart technology that controls the height of the ropes used in construction, for the ships passing under the bridge. The system detects the tension of the ropes in real-time to adjust the height automatically to ensure that the ships passing underneath can do so safely, thus ensuring safety in construction work.- Reference projects: Yi Sun-sin Bridge, Palyeong Bridge, Gogunsan Bridge, Cheonsa Bridge

- Intellectual property right: Registered Patent 10-1190338

-

Gantry of an irregular suspension bridgeA gantry is a massive work equipment that looks like a giant gate. Even when the distance between the cables on each side is not even while building a bridge, it allows using a light-weight, mobile work platform that is highly efficient for construction. By using this equipment instead of the massively expensive sea cranes, it is possible not only to save the cost but also to reduce the construction time.

Gantry of an irregular suspension bridgeA gantry is a massive work equipment that looks like a giant gate. Even when the distance between the cables on each side is not even while building a bridge, it allows using a light-weight, mobile work platform that is highly efficient for construction. By using this equipment instead of the massively expensive sea cranes, it is possible not only to save the cost but also to reduce the construction time.- Reference project: Gogunsan Bridge

- Intellectual property right: Registered Patent 10-1405010

-

-

2. Cable-Stayed Bridge Construction TechnologyThis technology is for building a bridge that supports the road using cables that are diagonally stretched from the towers. Starting with the Seohae Bridge, we have accumulated technology through 14 successful cable-stayed bridge projects in and out of South Korea. Leveraging this experience, we have developed the compact cable installation technology that can minimize the vibration of the cable due to wind and the load cell technology for measuring the tension of the cable, which is essential for managing the form of the bridge and ensuring its safety.

-

Compact multi-strand cable installation technologyThis is a state-of-the-art machine that installs strong cables that are made by bundling multiple strands of thin cables. With this machine, it is possible to build a bridge that is safe even in the face of wind and vibration while making the bridge stronger even with less material to save the construction cost.

Compact multi-strand cable installation technologyThis is a state-of-the-art machine that installs strong cables that are made by bundling multiple strands of thin cables. With this machine, it is possible to build a bridge that is safe even in the face of wind and vibration while making the bridge stronger even with less material to save the construction cost.- Reference project: Sepung Bridge

- Intellectual property right: Registered Patent 10-1299963

-

Development of the fiber-optic loadcells to control the tension on the cableMeasuring the tension of the cable precisely is very important for the management of the structure and safety in building a cable-stayed bridge. For this, we have developed a fiber-optic technology with improved durability and precision, making our tension measurement even more accurate. Also, the tension sensor (loadcells) that were used during construction can be used also during the operation of the bridge, allowing continued real-time monitoring of the changes in the tension on the cable.

Development of the fiber-optic loadcells to control the tension on the cableMeasuring the tension of the cable precisely is very important for the management of the structure and safety in building a cable-stayed bridge. For this, we have developed a fiber-optic technology with improved durability and precision, making our tension measurement even more accurate. Also, the tension sensor (loadcells) that were used during construction can be used also during the operation of the bridge, allowing continued real-time monitoring of the changes in the tension on the cable.- Reference project: Sector 5, Seohae-line

- Intellectual property right: Registered Patent 10-1326726

-

-

3. Girder Lifting and Installation TechnologyThis technology is needed to lift the upper deck of a bridge, which is called a girder. This technology, which lifts the girders on both sides, makes the installation of pre-cast concrete girders that are mainly used in long maritime bridges and pre-cast concrete segment girders more economical and faster. We have also secured the pre-fab segment technology, which automates the management of the form and allows for more precise construction work.

-

Lateral back-to-back liftingUnlike the existing lifting method, which can install only one girder a day, this new technology makes it possible to lift two girders back-to-back, doubling the speed of girder lifting. Since the girders are lifted as the balance between left and right is maintained, the load on equipment is reduced, opening a more economical way to lighter equipment.

Lateral back-to-back liftingUnlike the existing lifting method, which can install only one girder a day, this new technology makes it possible to lift two girders back-to-back, doubling the speed of girder lifting. Since the girders are lifted as the balance between left and right is maintained, the load on equipment is reduced, opening a more economical way to lighter equipment.- Reference Site: Temburong Bridge Project CC2

- Intellectual property right: Patent Application 10-2017-0154694

-

Development of the pre-fab segment shape management installation systemThis automated system makes it possible to assemble pre-fab concrete components more accurately for building bridges or overpasses. The computer automatically calculates the shapes and forms of each segment and adjust them accordingly, making it possible to make and install such segments faster and more precisely, minimizing construction errors and reducing construction time.

Development of the pre-fab segment shape management installation systemThis automated system makes it possible to assemble pre-fab concrete components more accurately for building bridges or overpasses. The computer automatically calculates the shapes and forms of each segment and adjust them accordingly, making it possible to make and install such segments faster and more precisely, minimizing construction errors and reducing construction time.- Reference project: The MCRP, the Philippines

- Software developed: DLPSM

-

-

4. Large Structure Foundation Construction TechnologyThis technology is used to construct the foundation, which is located at the bottom of a building or a bridge to support the upper structure. We construct the foundations of large structures such as long, special bridges like suspension bridges or cable-stayed bridges in a fast and safe manner, securing the core technologies to improve quality and reduce cost.

-

Technology to optimize the support of the foundationThis technology is used to measure the strength of the weathered zone ground, where it is more difficult to measure the strength of the ground. Based on the findings of this analysis, it is now possible to design the foundation of the building to provide maximum support. This, in turn, makes it possible to build the foundation that supports economy and safety.

Technology to optimize the support of the foundationThis technology is used to measure the strength of the weathered zone ground, where it is more difficult to measure the strength of the ground. Based on the findings of this analysis, it is now possible to design the foundation of the building to provide maximum support. This, in turn, makes it possible to build the foundation that supports economy and safety.※Weathering zone: A ground where the rocks are exposed to weathering.

- Reference project: Sungai Kebun bridge project, Temburong Bridge Project CC3, Honam Express Railway, etc.

- Intellectual property rights: Registered patents 10-0847096, 10-1011013

-

Technology to strengthen the vertical and lateral support of the foundationThis technology strengthens the foundation to support a large structure while ensuring safety. The supporting capacity of the large piles cast at the site is enhanced using two different methods. First, a special strengthening fluid is injected at the bottom of the piles to enhance their capabilities to withstand vertical loads. Second, steel wires are installed on the piles to withstand lateral loads in an effective manner, as well.

Technology to strengthen the vertical and lateral support of the foundationThis technology strengthens the foundation to support a large structure while ensuring safety. The supporting capacity of the large piles cast at the site is enhanced using two different methods. First, a special strengthening fluid is injected at the bottom of the piles to enhance their capabilities to withstand vertical loads. Second, steel wires are installed on the piles to withstand lateral loads in an effective manner, as well.- Reference projects: Busan Angol Bridge, Hongseong-Songsan Railway, Poseung-Pyeongtaek Railway, etc.

- Intellectual property rights: 10-0992751, 10-1069815, 10-1152265, 10-0990201

-

Rapid aquatic construction technologyThis state-of-the-art technology is used to construct the foundation in the water. A circular, temporary wall structure is constructed first to cut off the water and create a dry construction environment. Or, a pre-fabricated, special structure (floating PC house) can be used to construct the foundations fast and safely.

Rapid aquatic construction technologyThis state-of-the-art technology is used to construct the foundation in the water. A circular, temporary wall structure is constructed first to cut off the water and create a dry construction environment. Or, a pre-fabricated, special structure (floating PC house) can be used to construct the foundations fast and safely.- Reference projects: Temburong Bridge Project CC2 & CC3, etc.

- Intellectual property rights: 10-1816834, 10-1816835, 10-2004960, 10-2139722

-

-

5. Performance-Based Concrete Material TechnologyThis is a material technology that maximizes the quality and functions of civil structures by enhancing the performance of concrete materials and is composed of non-compaction/fully-mechanized casting of concrete, non-cracking concrete, and winter season accident-prevention paving technology that prevents freezing of the road surface.

-

High concrete fluidity technologyThis low-cement self-filling concrete production technology makes it possible that, without adding more cement to the concrete of ordinary strength, the fluidity and viscosity can be improved, making the concrete flow like water without compaction to fill in the mold, allowing high-quality concrete structure construction.

High concrete fluidity technologyThis low-cement self-filling concrete production technology makes it possible that, without adding more cement to the concrete of ordinary strength, the fluidity and viscosity can be improved, making the concrete flow like water without compaction to fill in the mold, allowing high-quality concrete structure construction.- Reference projects; Man-Gyeong Bridge, Yeongam-Haenam Bridge, Songsan-Sihwa Bridge, and more.

- Intellectual property rights: Registered patents 10-1985774, 10-1992232

-

Low-cement, low hydration-crack mass concrete technologyThis environmentally friendly concrete technology utilizes the slag from blast furnaces, which is a byproduct of the steel-making process and an environmentally friendly, low-carbon material, as well as anhydrite (a sulfate mineral). This technology allows achieving the same level of concrete structure using only 10 to 30% of cement compared to conventional concrete, reducing carbon emissions significantly. It also reduces cracks as it can decrease the amount of heat emitted when concrete hardens.

Low-cement, low hydration-crack mass concrete technologyThis environmentally friendly concrete technology utilizes the slag from blast furnaces, which is a byproduct of the steel-making process and an environmentally friendly, low-carbon material, as well as anhydrite (a sulfate mineral). This technology allows achieving the same level of concrete structure using only 10 to 30% of cement compared to conventional concrete, reducing carbon emissions significantly. It also reduces cracks as it can decrease the amount of heat emitted when concrete hardens.- Reference projects: Busan Angol Bridge, Singapore TTP1, etc.

- Intellectual property right: Registered patent 10-1656853

-

Heat-emitting concrete pavement technologyThis concrete pavement technology makes it possible to make a concrete material that conducts electricity using carbo nano tubes (honeycomb-like carbon structures). As a result, the concrete emits heat with a small power supply keeping it from freezing even in an extreme cold.

Heat-emitting concrete pavement technologyThis concrete pavement technology makes it possible to make a concrete material that conducts electricity using carbo nano tubes (honeycomb-like carbon structures). As a result, the concrete emits heat with a small power supply keeping it from freezing even in an extreme cold.- Intellectual property right: Registered Patent 10-2543840

-